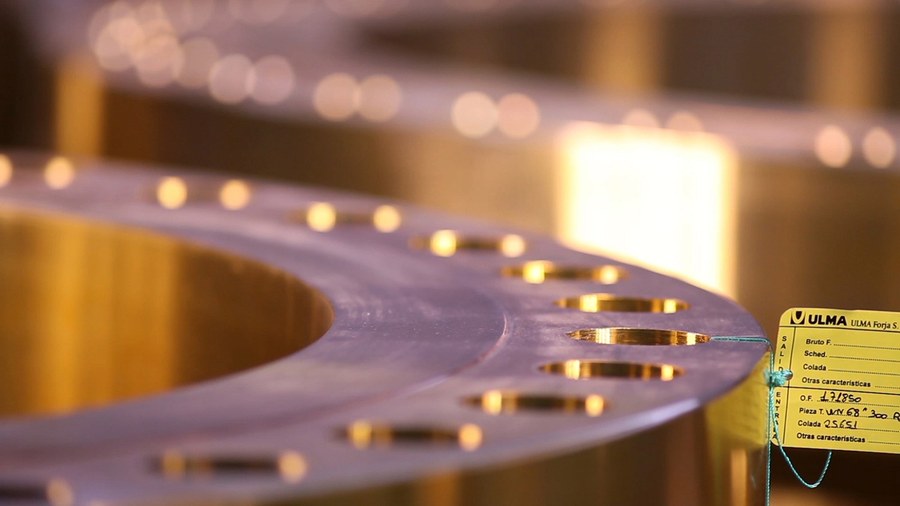

Ulma Forged Solutions

The new ULMA Piping destruction testing laboratory, ready to go

ULMA Piping has made significant investments into updating the existing laboratory. In comparison with the above, the new laboratory is in the ULMA Piping forgework building and has the most advanced technologies in:

- Mechanical testing: Involves physically testing a portion of the material with the aim of determining its properties (resistance, ductility, durability, etc.).

- Metalography – Materialography: The technique that studies the microstructural or elemental characteristics of a metal, which are also intimately related to physical, chemical and mechanical properties. It is not just a basic tool for classifying metals, it is also for polymer, ceramic materials and the different possible combinations of compound materials. This is why it also has the name Materialography.

- Chemical Analyses: This technique is used to determine the chemical composition of a material; in other words, it offers information about the different elements present in the sample analysed. This makes it possible to determine the major and minor components and/or traces of elements in different types of materials.

- Corrosión: Material corrosion and ageing tests, under the customer’s specifications, Spanish and international standards. One of the objectives of the 2016-2017 certification plan is to begin the process of obtaining ISO 17025 accreditation. Customers increasingly more often require that ULMA uses laboratories that have ISO 17025 accreditation, thus the importance of certifying the new laboratory. ISO 17015 is an international standard developed by the ISO (International Standards Organisation), which establishes the requirements that testing and calibration laboratories must comply with. It is a quality standard based on a series of ISO 9000 quality standards. Although this standard has many aspects in common with the ISO 9001 standard, it is distinguished in that the main objective is to provide accreditation of entities’ testing and calibration competence, by the corresponding regional entities. The standard is applied by testing and calibration laboratories with the aim of demonstrating that they are technically competent and capable of producing technically valid results.