ULMA Packaging and ULMA Handling Systems open their new facilities

The new plant of ULMA Packaging has 5,000 m2 distributed across two storeys – 4,000 m2 of which are intended for the production area and the rest to offices– and is expandable in the future with an adjoining area of 4,000 m2.

This new production plant responds to the need for growth of the heat-sealing activity, which has quadrupled sales in the last four years, and has sought to provide space for the new product range, which focuses on custom assembly of heat-sealing machines. This activity and its rapid growth have also involved a strong increase of the human team in the business. In recent years, the jobs directly related to the heat-sealing activity have tripled, growing from 30 to 90 people. On the other hand, this growth has also allowed the indirect creation of new jobs in local supplier companies.

The new plant offers a production capacity of approximately 400 machines per year, with the option of expanding the construction in the future thanks to an annex building that has already been acquired and which would double the current capacity. In the production area, lean assembly lines have been installed for the production of heat-sealing machines, based on a management model focusing on the creation of a production flow to offer maximum value to customers, using the minimum resources necessary. A small auxiliary boiler and maintenance workshop was also incorporated. This involved the application of the most innovative technologies in terms of sustainability and energy consumption, achieving an energy-efficient plant. The construction and transfer took place in a record time of less than one year.

As for ULMA Handling Systems, “the quality, engineering and professionalism of the human engineering team of ULMA Handling Systems have made possible, in these 20 years of history in France, for our company to become a benchmark for logistics automation, with projects implemented in renowned companies in the large distribution, food & beverage and textile sectors, among others”, said Julian Garmendia, Director of ULMA Handling Systems France.

The engineering currently has a market capture of €200 million for the next two and a half years, specifically in projects being developed for companies such as INTERMARCHÉ, PROCLINIC, ENTREPINARES, SYSTEME U, ELHIS, CÁRNICAS TELLO, BRIDOR, PAPELERÍA SAMSENG, and MARINE SPARE PARTS, among others.

In this context, it is worth mentioning the signing of an important agreement between the company LUG, belonging to the well-known France-based supermarket group INTERMARCHE and ULMA for the execution of an ambitious logistics automation project. This project marks an important milestone in the history of ULMA Handling Systems, placing it as the leading logistics engineering company in the Large Distribution sector.

Recently, the engineering area has moved its logistic operations centre from Serris to Orly, in an ambitious move to locate itself in the main enclave of France and Europe.

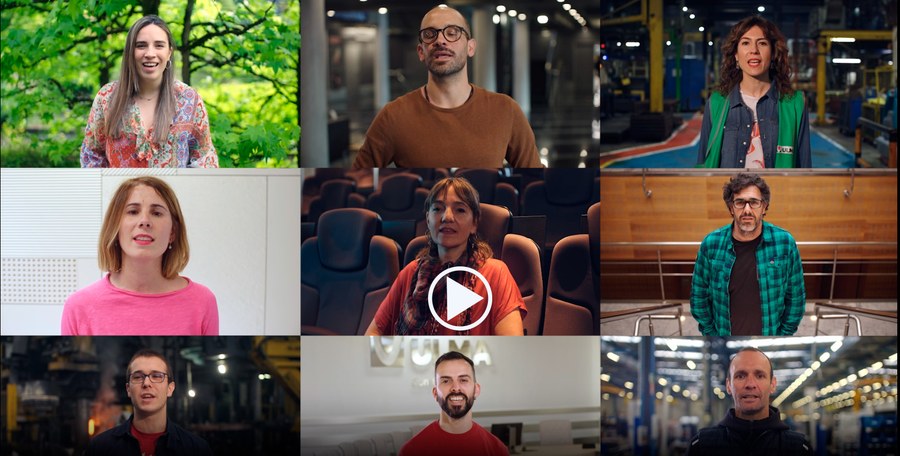

We also present two videos that summarise the opening events: