ULMA Piping signs an agreement for the supply of special flanges for a Korean engineering company

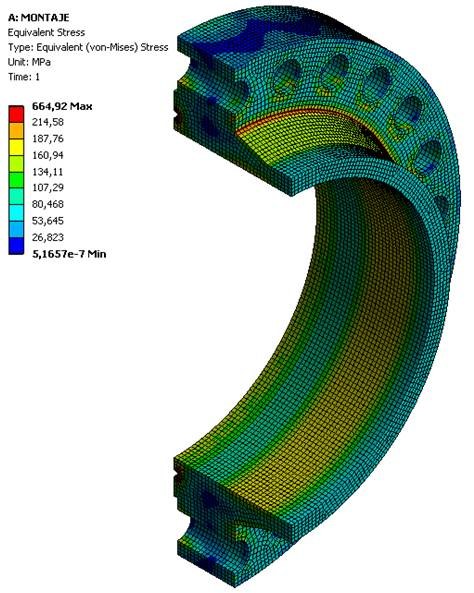

The particularity of this project consists in the fact that all the flanges to be supplied are non-standard. Therefore, and in tight collaboration with the client, the ULMA engineering team has developed all the calculations necessary to proceed with the correct design of the flanges. In order to offer higher added value, ULMA has verified all the results by means of a finite elements analysis (FEM), this finally being validated by the client.

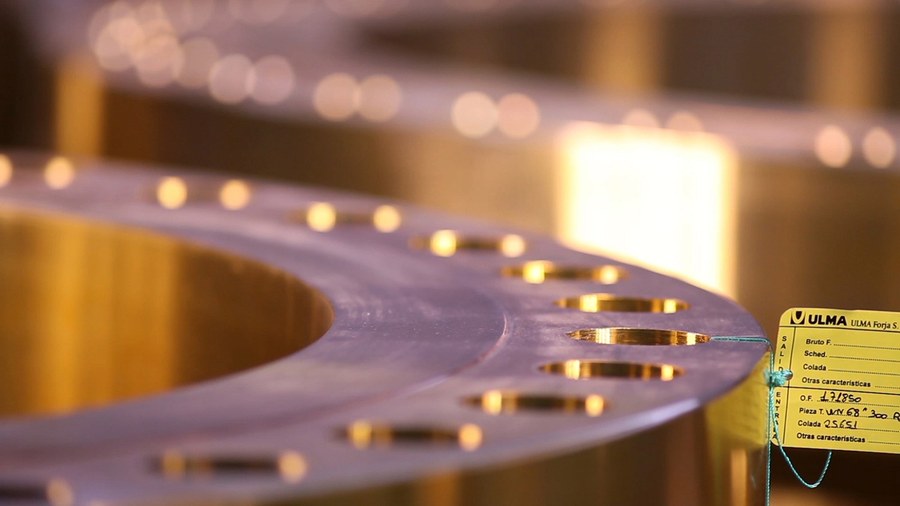

This is not the first time that ULMA Piping offers this type of service to engineering companies; however this is a very particular case, as the flanges exceed 5 Ton, and even up to 17 Tn. Fruit of this tight collaboration, the client has placed all its trust in ULMA, also requiring, and for the first time ever, the complete supply of the seals corresponding to the flanges. To do that, several manufacturers have been contacted and approved by the end client (approval and homologation from the final client has to be obtained to participate in the project) and the design of the most appropriate seals capable of supporting the work conditions has been jointly developed.

At the moment ULMA continues working on the possibility of offering the client the execution of the hydrostatic tests. These tests are fundamental in this type of project before the definite installation in the line to ensure correct performance and of the staunchness of the complete unit (flanges + seals + screws).

This order only goes to strengthen the strategic positioning of ULMA Piping in the project business, initiated some years ago, and more specifically in the Korean market, where in 2011 it decided to open its own commercial office.