ULMA Piping, certified for flange design and calculation by the API (American Petroleum Institute) and ISO (International Standardization Organization)

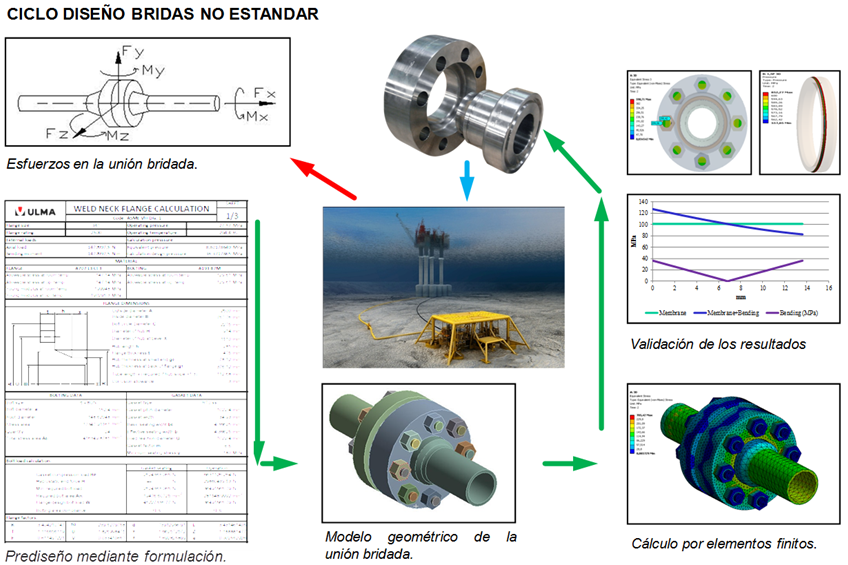

For approximately the last three years, ULMA Piping has been learning and incorporating new methods and technologies for the design of non-standard flanges. These flanges have special characteristics requiring a specific design process to fit the working conditions of a specific application. The most common non-standard characteristics are:

- Large pipe diameters. ULMA has designed flanges of up to 102 inches in diameter, meaning an internal pipe diameter of 2.6 metres.

- High pressures. Flanges for extremely high pressure applications.

- Other characteristics: Non-standardised pipe dimensions, high external stress, etc.

Design and validation of these flanges involves calculations, either via the application of formulas or via more advanced techniques such as the finite element method. These calculations ensure the following:

- Verification the flanges and bolts have been correctly designed to withstand the operating and assembly stress required by their installation process.

- Assurance that there will be no joint leakages provided the flange has been correctly manufactured and installed.

In February, ULMA Piping obtained its first certification for flange design and calculation from the API (American Petroleum Institute) and ISO (International Standardization Organization).