Ulma Conveyor Components

ULMA Conveyor Components invests in a new machining centre to improve its competitiveness in the heavy-load market

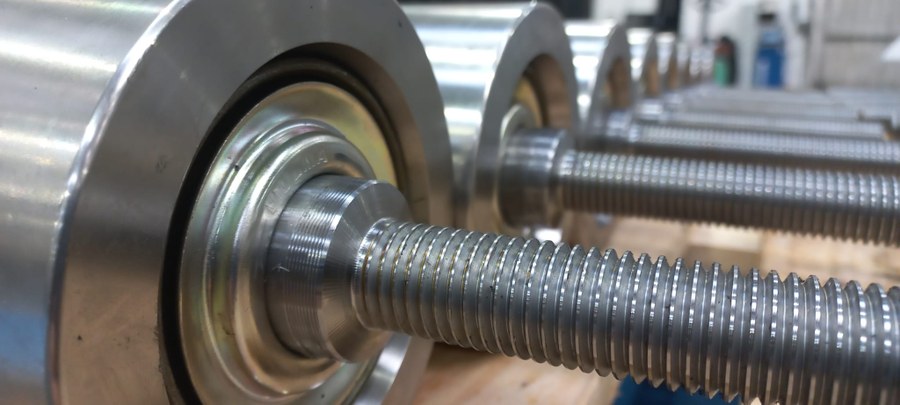

ULMA Conveyor Components, as part of the manufacturing process improvement plan it is currently involved in, has incorporated a new machining centre into its HDC line with the aim of eliminating the time lag between the manufacture of the roller shaft and the rest of its operations. A key action for the production chain of the product in which they are currently focusing on.

With the aim of finding a complete solution for the manufacture of the shaft that will eliminate the imbalances and handling required by the current process and having analysed a number of different solutions, this investment includes a 3-shaft machining centre and a double pallet exchanger with an integrated gantry system for automatically loading and unloading of shafts.

This new solution will enable ULMA Conveyor Components to improve its response time in the heavy load market and offer improved machined finishes that are highly valued in a very demanding market.