MK Shoring System demonstrates its high load-bearing capacity in the construction of the Waste Conversion Plant in Pavia.

Approximately 230,000 tonnes of material will be processed at the plant annually, 99% of which will be incinerated to generate 200,000 megawatts of electricity, as compared to the 40,000 MW currently produced.

MK Shoring Towers were used to prop the 6 m thick transverse beam, built at a height of 21 m, to support the hopper that feeds the plant’s large turbines. Assembly was performed in situ quickly, safely, and with continuous oversight from an ULMA technician throughout the entire process. The towers were set in place with cranes, and after use could be moved and disassembled using, only the wheels integrated into their bases.

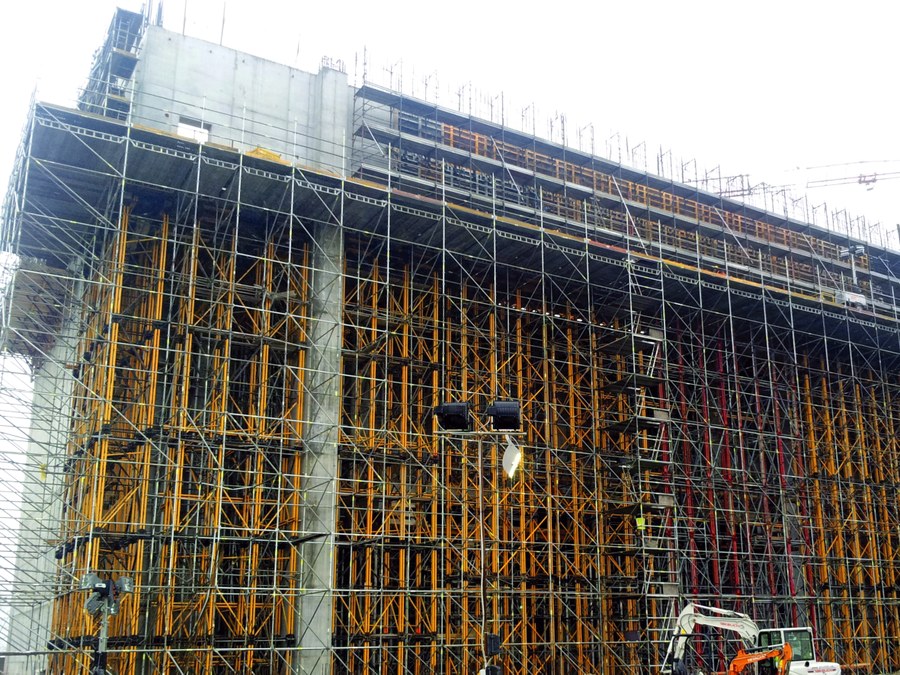

For the various floors and internal subdivisions onsite, aluminum ALUPROP towers were used. The walls, which will reach a total height of 40 m, along with the buttresses, were built with ORMA Panel Formwork set on BMK Climbing Brackets anchored to the previously poured concrete.

The perimeter of the work area was covered with BRIO Multidirectional Scaffolding and BRIO Stair Towers, providing complete and safe access for installing the steel reinforcement.

In order to guarantee safety while pouring the slabs, working platforms with MK walers were used to cover the gap to the floor below.

ULMA met the most demanding requirements of this type of project: reducing costs while providing solutions that are both high quality and safe.