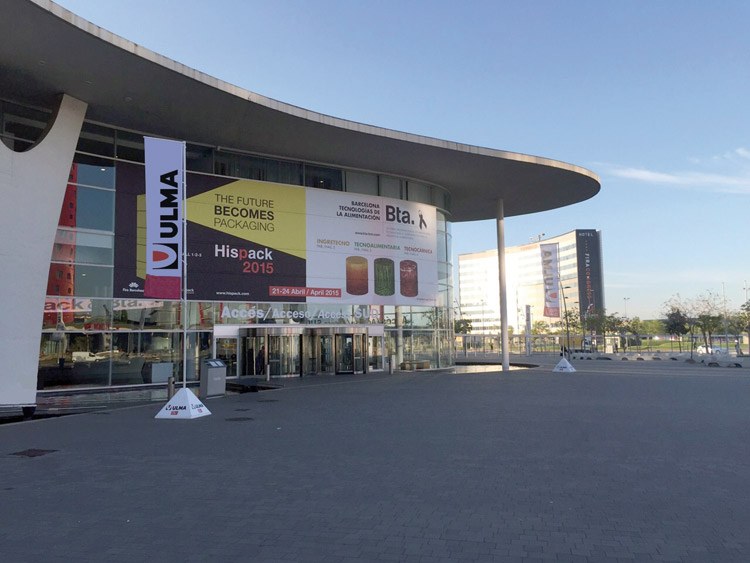

ULMA, great protagonist at the HISPACK-BTA exhibition

ULMA ARCHITECTURAL SOLUTIONS  ULMA Architectural Solutions presented its Stainless Steel Drainage Solutions at the BTA Food Technologies Exhibition.

ULMA Architectural Solutions presented its Stainless Steel Drainage Solutions at the BTA Food Technologies Exhibition.

One of the great pieces of news from the new range presented is the HygienicPro model. An original and exclusive draining concept developed by Blücher and distributed by ULMA, which has more than 50 years of experience in design and manufacturing in the sector.

All these solutions presented by ULMA Architectural Solutions in its new stainless steel catalogue place it at the forefront of the development of personalised and sustainable solutions for the construction sector, in addition to being a symbol of quality and seal of quality in construction.

ULMA PACKAGING  For its part, ULMA Packaging exhibited its most original developments at the HISPACK exhibition, the benchmark fair in the area of the domestic market.

For its part, ULMA Packaging exhibited its most original developments at the HISPACK exhibition, the benchmark fair in the area of the domestic market.

In the area of heat-sealing, two models of the new range of high efficiency TSA heat-sealing machines. The TSA 680 model for vacuum skin applications of fresh products that project above the height of tray (protruding) and the TSA 875 model, integrated in a line in which all the elements were self-manufactured.

In the Flow Pack area, three different models for three times of containers. An ARTIC with side sealing for slices in a very practical re-sealable container. The FV 35 packing machine that belongs to the FLOW-VAC® family, developed to create shrink-wrap vacuum bags that adapt to the length of the product to be packaged. Finally, the high-speed flow pack FR 500 packing machine, designed to package industrial baked products and chocolate, which possesses an automatic feed system to guarantee its high cadence of up to 800 pack/min.

Within the Thermoforming solutions, the TFS 407 DARFRESH® with CRYOVAC® film for vacuum skin packaging and the high-efficiency TFS 700 thermoformer designed for sliced meat products, which possesses a sanitisable and high-autonomy design to guarantee a production of 90 containers/min.

ULMA HANDLING SYSTEMS  strong>ULMA Handling Systems showed the automated logistical systems directed at producers, manufacturers and distributors of from various industrial and consumption sectors.

strong>ULMA Handling Systems showed the automated logistical systems directed at producers, manufacturers and distributors of from various industrial and consumption sectors.

Undoubtedly, considering the real operation of its automatic rust-free automatic storage system and the automatic palletising systems were the most prominent activities of this stand.

The ULMA rust-free storage system is specially designed for the food sector and has unique characteristics to improve the quality of the processes and flexibility in the adaptation to the logistical structures of clients. This system, in addition to ensuring the traceability and optimal quality of the products for a greater safety control, reduces the processing times of the food while delaying the final destination assignment.

In turn, the automatic palletising system presented by ULMA Handling Systems is proof of the different functionalities offered by engineering in the End-of-Line systems. It has the best partners in robotics and a great knowledge of material flow automation systems in the Supply Chain and in the Cold Chain.

ULMA INOXTRUCK  ULMA Inoxtruck, participated for the second time in the Hispack –BTA fair, where it exhibited its whole range of sanitisable stainless-steel equipment for handling loads, designed for the food industry under the parameters of sanitisability, ergonomics and low maintenance, facilitating its daily cleanliness without affecting the provisions and durability.

ULMA Inoxtruck, participated for the second time in the Hispack –BTA fair, where it exhibited its whole range of sanitisable stainless-steel equipment for handling loads, designed for the food industry under the parameters of sanitisability, ergonomics and low maintenance, facilitating its daily cleanliness without affecting the provisions and durability.

Solutions for horizontal cargo movement (hand and electronic pallet trucks) were presented in addition to solutions for elevation and handling of loads (electronic and electro-manual applicators), a full range of auxiliary equipment for the change of spools or moulds in packaging equipment and the range of turning equipment, especially for the turning of DIN 9797 cutter trolleys. The exhibition of an electronic pallet transfer machine within an urn immersed in pressurised water, simulating movements, which generated expectation among the visitors.