ULMA Conveyor Components gets homologation order in Minera Escondida

Minera Escondida is a mine operated by the multi-national BHP Billiton. It was founded in 1988, and it’s the highest producing copper mine in the world. It’s located 170km south west of the city of Antofagasta in the second region of Chile and it’s focused on producing concentrated copper and copper cathodes.

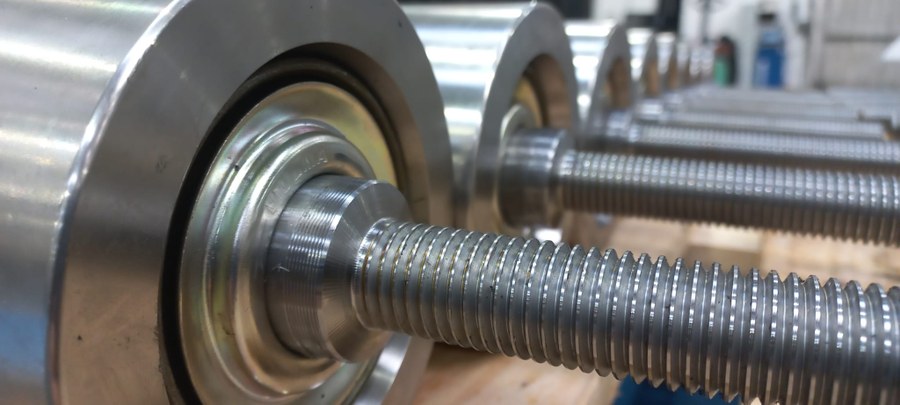

The order ULMA Conveyor Components will be handling consists of 100 return garlands that will hopefully solve the cleanliness problems on one of the belts in the facility. 95 helical garlands will be shipped along with 5 improved ones with polyurethane rings for the customer to try so they can compare the two solutions and decide which one best suits their needs.The garlands will be installed on a CV25 belt, which is a 1 km long mobile conveyor located inside the new Óxidos plant (OLAP). It has a belt width of 1600 mm and can transport around 3000 tn/h.

With this order, ULMA Conveyor Components has reinforced its position as one of the most important distributors of mining materials in Chile.